Producing Customized Uniforms and Merchandise for the Shizuoka Blue Revs Pro Rugby Team

02/14/2023 Digital Printing

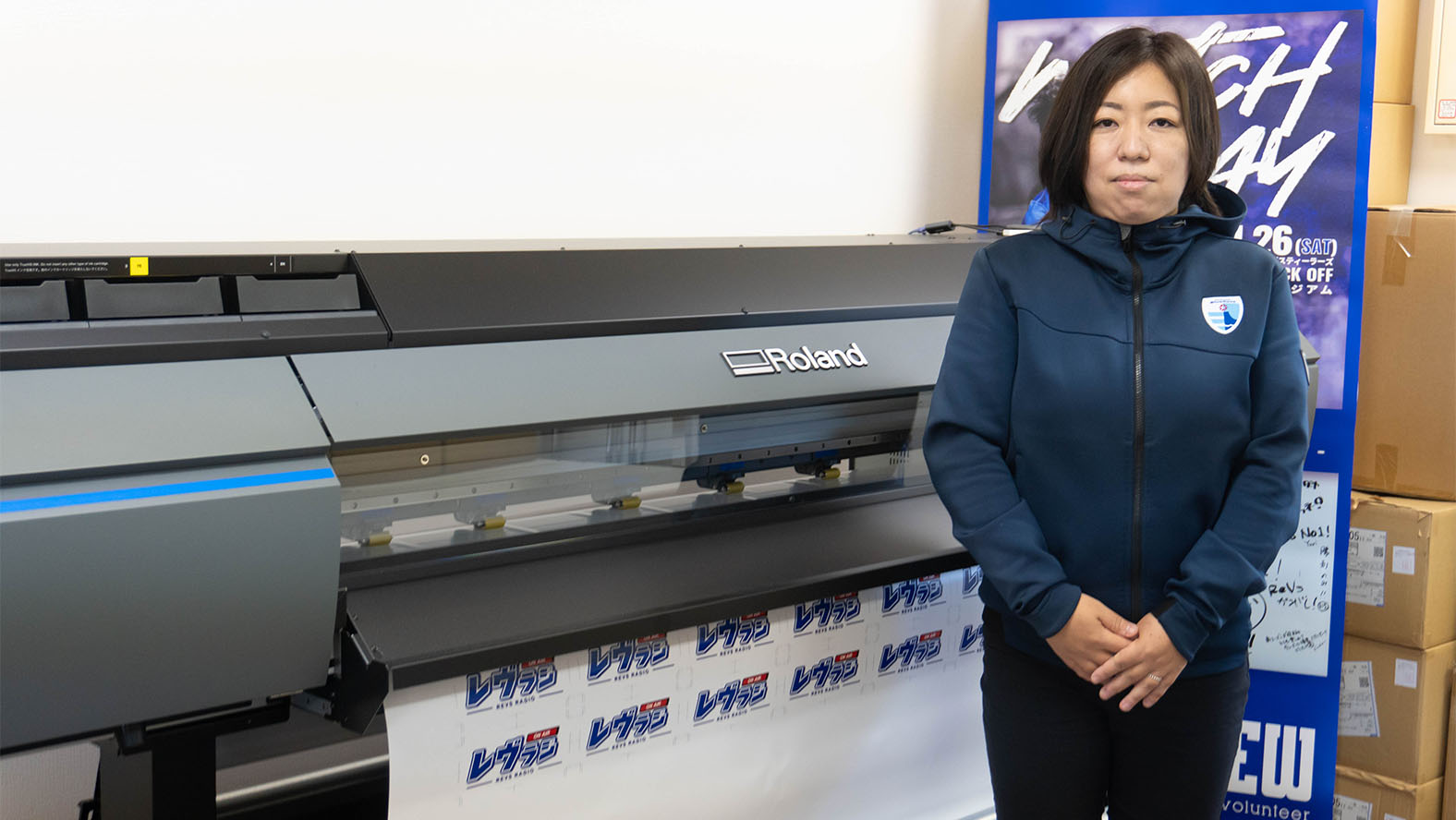

The Shizuoka Blue Revs (formerly known as Yamaha Júbilo), which is a team playing in Japan Rugby League One, recently kicked off its second season. Their management company is using Roland DG’s TrueVIS SG3-540 wide-format printer/cutter to customize uniforms and produce original merchandise for the team and their fans.

We spoke with Asuka Hirano (in photo) in charge of creative design at the Business Operations Div. PR & Promotion/Creative of the team’s management company Shizuoka BlueRevs Co., Ltd. based in Iwata City in Shizuoka Prefecture, Japan.

From “Yamaha Motors Rugby Football Club” to professional team representing the Shizuoka Area

Roland DG: What was the origin of the Shizuoka Blue Revs?

Hirano: The team used to be known as “Yamaha Júbilo,” which was Yamaha Motor’s industrial league rugby team. It was rebranded as the “Shizuoka Blue Revs” professional rugby team following the launch of the new Japan Rugby League One pro competition in 2021. Our management company was also established as an independent subsidiary. The second season of League One kicked off December 17, 2022.

It was originally Yamaha Motor’s team based in Iwata City in Shizuoka Prefecture. The biggest change since being renamed the Shizuoka Blue Revs is that the team’s host area now covers all of Shizuoka Prefecture. During the 2019 Rugby World Cup held in Japan, the match where the Japanese team beat the powerful Ireland team was played in Shizuoka, and it was so exciting! Yet the fact is that as a sport, rugby is still not so familiar around Shizuoka. We are focusing our efforts on grassroots publicity activities to build up the team that is now supported and adored by everyone in the prefecture.

Producing uniform numbers and merchandise as well as stadium exhibits

Talk about how you began using the TrueVIS SG3-540 wide-format printer/cutter.

That came about when President Takashi Yamaya suggested the idea of producing uniform numbers and merchandise in-house. I had experience using inkjet printers at my previous workplace, so I thought it would be possible to make accessories right here if we could use a wide-format printer for the printing and transfers. After doing some research, I found out that Roland DG was a manufacturer located nearby in Hamamatsu City, Shizuoka, so I looked into the available options. We were initially thinking about a desktop model, but in September 2022 we settled on the wide-format TrueVIS SG3-540 with its printing and cutting functions because we planned to eventually make large signs in the future.

We have only been using the printer for a while, but our next project is to begin producing merchandise and we have already started making some pre-season uniform numbers.

The SG3-540 inkjet printer in use at the Blue Revs merchandising studio.

What are your impressions after using the SG3-540?

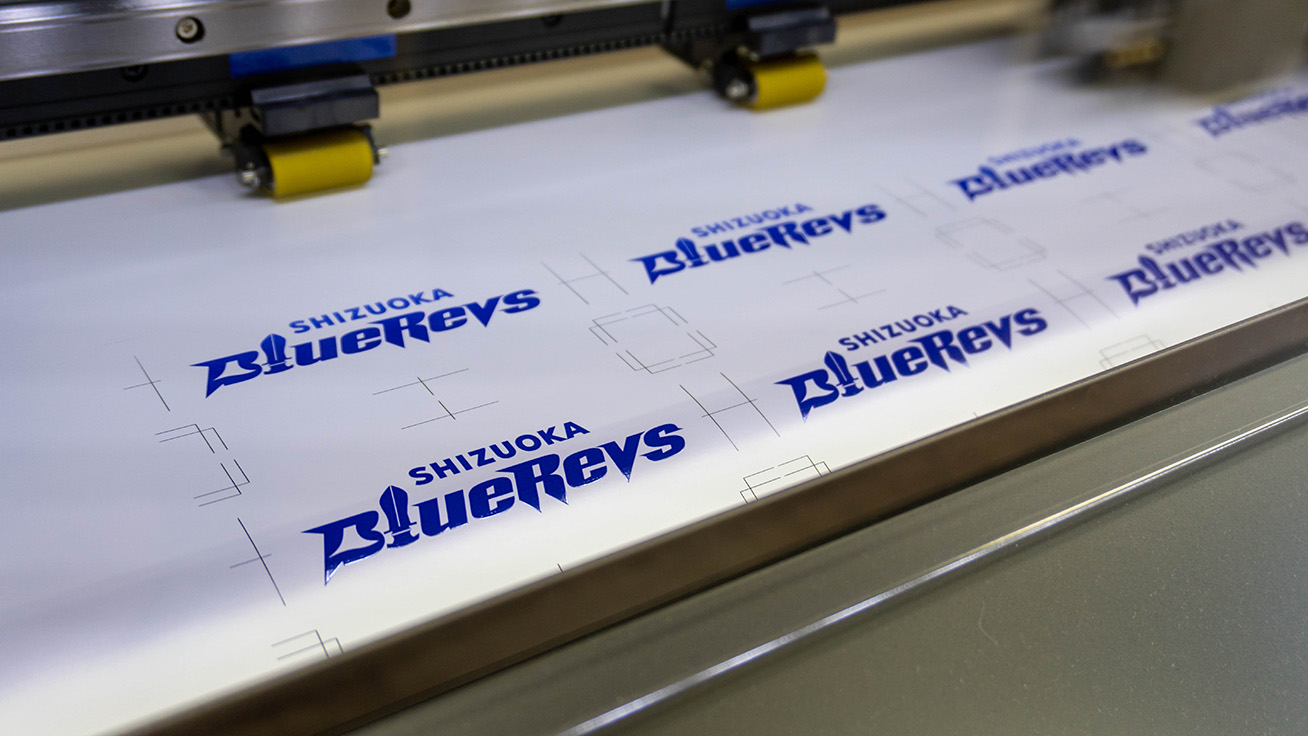

The colors look so great and it prints the blue team color of the Shizuoka Blue Revs so vibrantly; the contour cutting is also perfect. The team logo is designed with many fine lines, and while we had difficulties reproducing this design with embroidery, the SG3-540 cuts them out cleanly.

Shizuoka Blue Revs logo printed in vivid color.

What features do the rugby uniform numbers have?

Numbers cut with the SG3-540 are heat-transferred onto uniforms.

Rugby differs from soccer or other team sports in that there is no direct connection between the uniform number and each player’s name. If players are unexpectedly injured or assigned to different positions, numbers need to be added quickly to uniforms before a match. In the past, the only way we could do this was to urgently outsource this work. After we began using the SG3-540, our first step was to quicky add numbers to uniforms in-house for pre-season matches.

Rugby is a high contact sport and some sections of the players’ uniforms are stretched and pulled, while other sections are not, but we have not had any of the numbers peeling off or becoming damaged at all. We are hoping to use the printer to update uniforms when there are other unexpected changes, like when team sponsors announce new logos on short notice.

What types of merchandise are you making?

We started out with stickers, but now we are also producing tote bags, T-shirts, stadium jumpers and much more. Instead of outsourcing these items, we make them here in small lot batches, which means we can sell even single units of a particular item.

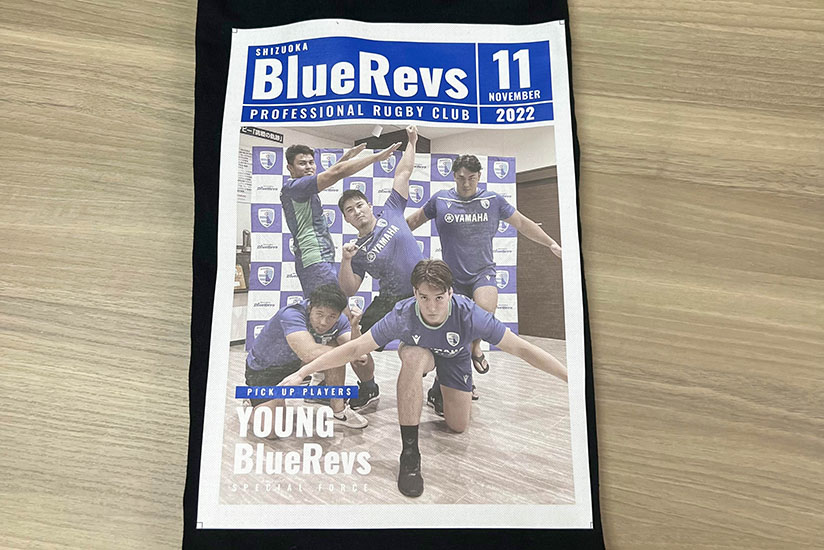

We recently had a go at producing merchandise featuring the team players portrayed with cartoon or magazine style designs. We had always wanted to produce merchandise that featured players, but were never able to because of the risk of leftover stock. With the inkjet printer, we are now able to select a few designs and produce a few units right here. We sell prototypes at event venues as limited-edition items, and if those items end up becoming popular amongst the team’s fans, we can then shift to full production. Merchandise featuring team captain and South Africa national team player Kwagga Smith in particular sold much better than we had expected. T-shirts printed with previous uniforms also proved very popular. Now we can visualize the sales demand for each type of product, or see if fans actually like some of our more daring designs.

Unique tote bag using a comical design to feature a player.

-

Merchandise featuring cartoon-style designs are also popular with players.

-

An example of a T-shirt with players’ social media photos designed to look like a magazine cover.

It looks like you are also printing banners and other signs.

The Shizuoka Blue Revs have an official volunteer group called “Revs Crew.” Until now we had used the same volunteer banners around the stadium throughout the year, but the staff in charge of volunteers suggested that we change the designs for each match and to include a space where players and volunteers can write messages. Outsourcing the production for these banners would increase cost and time, so we decided to make them here. This proved very popular during recent matches and we received a number of messages from the team volunteers. The banners are a great communication tool for volunteers and they also help to boost motivation, so we hope to continue producing them.

Volunteer banners feature lots of messages of support from volunteers.

Making content to connect with fans

What designs are you planning going forward?

There are some 50 players in the team, which makes it difficult to feature all of the players equally. Being able to produce merchandise in small lots gives us more opportunities to feature players on those items. This not only helps to boost the motivation of players, but also provides a way for us to create content that gives fans a greater sense of attachment or emotional connection with the players.

Part of the sales of team player portraits or merchandise featuring players goes back to the players themselves. This fact is still not very well known amongst fans, so we hope to make fans aware that they are directly supporting the players as we continue to develop more merchandise.

To make matches even more entertaining for fans, we are planning to provide a service for adding player numbers to uniforms sold at the stadium or uniforms that the fans already own.

What are your future aspirations?

Having customers attend their very first match and ensuring that they leave with a positive experience is a difficult task; this applies as well to rugby in general. I am certain that teams in other regions are also putting in just as much effort in this regard. There is a strong possibility that visitors who have a good experience at the stadium may return again later on.

We are planning a number of different methods aimed at keeping people interested in matches, such as holding events at shopping malls on weekends when there are many families with children, or using social media like Twitter to promote limited edition merchandise available at matches.

Thanks for the informative talk! We hope you are able to use the printer to produce uniforms that support the players as well as merchandise that helps connect them with fans.

See details of the Shizuoka Blue Revs here (Japanese text only)