Product News

06/25/2008

Roland DG Corporation

Roland Introduces New Professional CAM Software for MDX 3D Milling Machines

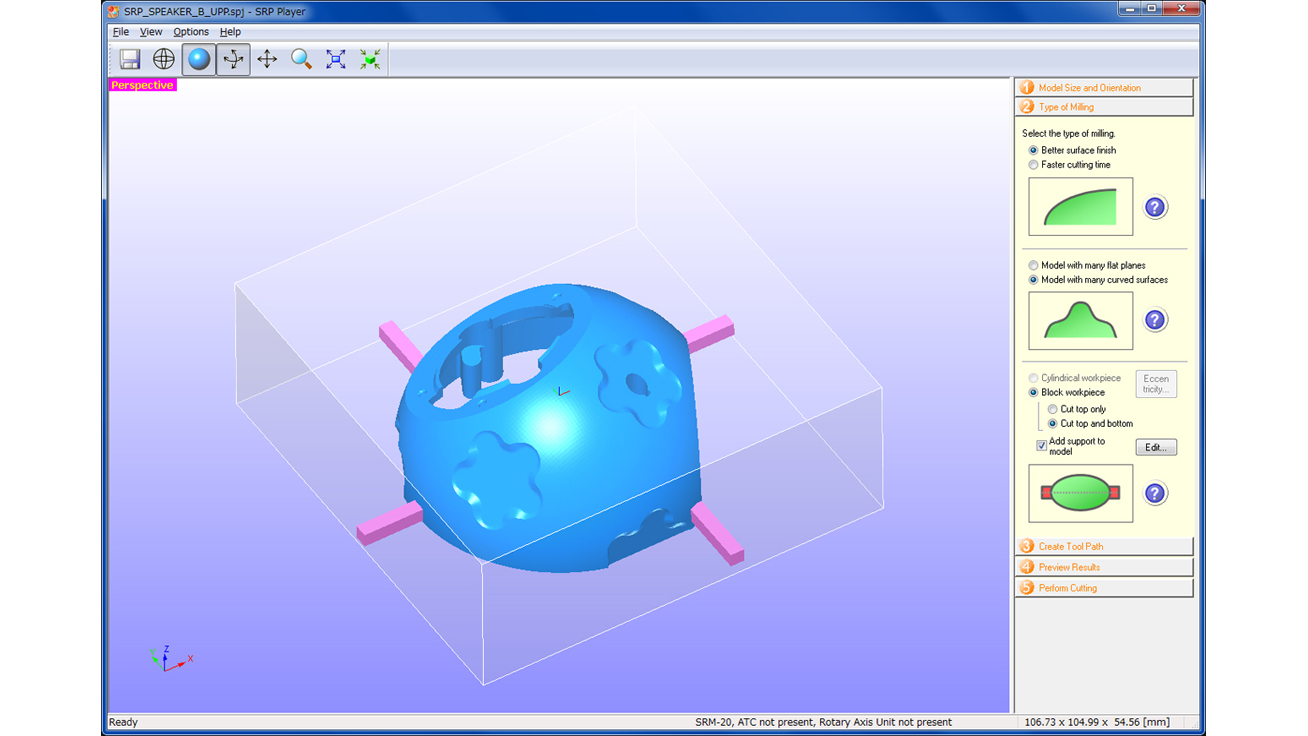

Hamamatsu, Japan, June 25, 2008 – Roland DG Corporation today announced the new SRP Player Pro surface-based CAM software for professionals involved in product design, including prototyping, production engineering, jig creation, and customized part and mold production. Designed for use with the Roland MDX series of 3D milling machines, SRP Player Pro allows professionals to fully optimize the capabilities of Roland’s most advanced Subtractive Rapid Prototyping (SRP) milling technologies.

“SRP Player Pro CAM software brings new levels of quality and productivity to the MDX production environment,” said Kiyoshi Sogo, Roland DG CAD/CAM application manager. “SRP Player Pro delivers exceptional surface and fitting accuracy for applications ranging from sink faucets to medical devices, cosmetic bottles, automotive mirrors, toys and more. For each application, SRP Player Pro software generates the optimum tool path at low tool-load and ensures smooth, precise milling for outstanding results.”

New SRP Player Pro Features:

‐ Powerful surface-based CAM software is designed to produce data with the highest degree of accuracy

‐ Designed to take full advantage of Roland MDX 3D milling machines including the MDX-40, 500, 650 and 540/540A/540S/540SA models

‐ Supports applications for a wide range of markets including prototyping, solid modeling, lost wax mold production, and the production of jigs, customized parts and molds

‐ All curved surface data including fine details is retained for smooth, accurate milling

‐ Generates the optimum tool path for each application from surface or polygonal data

‐ A new automatic smoothing function produces flawless shapes with both smooth, accurate, curves and sharp edges

‐ The low-tool load feature ensures stable milling operation by first milling the areas requiring a higher tool-load and then precision milling small features and details such as tiny holes and slits skipped during the rough cutting process

‐ Extends the lifespan of tools by reducing the impact of the milling operation on each tool

‐ Allows you to select and mill specific sections such as a line, circle or polygon to ensure the highest level of efficiency, quality and productivity

‐ Detailed parameter settings ensure professional precision and quality

‐ Provides easy-to-use, intuitive operation throughout the design and workflow processes

Roland MDX 3D Milling Machines

Designed for industrial applications, Roland 3D Milling Machines include two recent additions: the Professional MODELA PRO II MDX-540 and the Desktop MODELA MDX-40. These devices quickly and inexpensively produce prototypes and parts for small lot production in virtually any lab environment. MODELA PRO II machines mill a wide variety of materials including non-ferrous metals such as aluminum, brass and copper, plastics such as ABS and acetal, and chemical woods and resin. Intuitive operation panels are easy to navigate for the ultimate in ease of use.

The MODELA PRO II series includes four models: the MDX-540 standard model, the MDX-540S precision model, and the MDX-540A and MDX-540SA models which include an Automatic Tool Changer (ATC). With the optional rotary axis unit installed on S and SA models, the MDX achieves the highest levels of efficiency by operating fully unattended – milling all four sides of a prototype, from roughing through finishing, without operator assistance. SRP Player Pro software is also compatible with previous Roland 3D Milling Machines, including the MDX 650 and MDX-500.

-

Roland DG Corporation (TSE symbol 6789) - First Section, Tokyo Stock Exchange

Phone: +81 (0)53-484-1201 / Fax: +81 (0)53-484-1216